In modern power electronics, motor drives, and electromagnetic systems,

soft magnetic materials play a critical role in determining efficiency, thermal behavior, size, and reliability.

While circuit topology and control strategies receive significant attention,

magnetic material selection is often underestimated — yet it directly impacts system performance.

This page provides a practical engineering-oriented overview of soft magnetic materials

and explains how different material families are applied in real-world designs.

What Are Soft Magnetic Materials?

Soft magnetic materials are materials that can be easily magnetized and demagnetized.

Their primary function is to guide, concentrate, transmit, and convert magnetic energy

under alternating or dynamic magnetic fields.

They are widely used in:

- Transformers and inductors

- Motors and generators

- Power converters and PFC circuits

- EMI suppression and sensing applications

Key Magnetic Parameters That Affect Design

When evaluating soft magnetic materials, engineers typically focus on a few critical parameters

that have a direct influence on performance:

Magnetic Permeability (μ)

Permeability indicates how easily a material can be magnetized.

Higher permeability allows magnetic components to achieve the same inductance

with smaller core volumes, supporting compact designs.

Saturation Flux Density (Bs)

Saturation flux density defines the maximum magnetic flux a material can carry.

Materials with higher Bs are better suited for high-current or high-power applications

where compact size is required.

Coercivity (Hc)

Low coercivity means the material can be demagnetized more easily,

resulting in lower hysteresis losses in AC and high-frequency operation.

Core Loss

Core loss consists mainly of hysteresis loss and eddy current loss.

It becomes the dominant source of inefficiency as frequency increases,

making material selection especially important in high-frequency designs.

Thermal and Long-Term Stability

Stable magnetic properties over temperature and time are essential

for maintaining consistent performance in industrial and automotive environments.

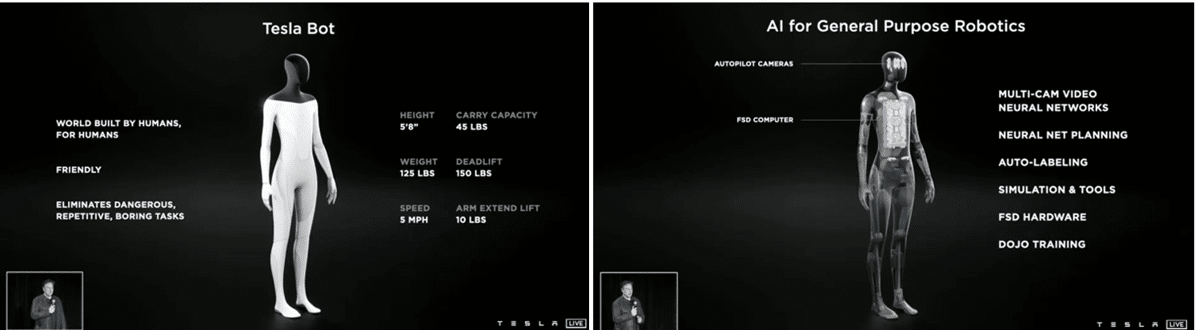

Common Soft Magnetic Material Families and Applications

Silicon Steel and Metal Alloys

Silicon steel and related iron-based alloys offer high saturation flux density and low cost.

They are widely used in power-frequency applications such as:

- Power transformers

- Industrial motors

Typical operating frequencies range from 50 Hz to 400 Hz.

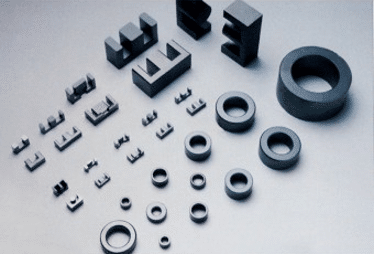

Ferrite Materials (MnZn / NiZn)

Ferrites are ceramic magnetic materials with very high electrical resistivity,

which significantly reduces eddy current losses at high frequency.

They are commonly applied in:

- Switch-mode power supplies

- High-frequency transformers and inductors

- EMI filters and RF components

NiZn ferrites are particularly suitable for very high-frequency and EMI-related applications.

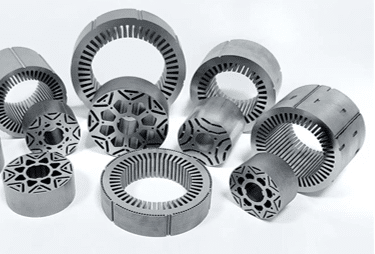

Metal Powder Cores and Soft Magnetic Composites (SMC)

Metal powder cores consist of insulated metal particles pressed into shape.

Their structure provides:

- Excellent DC bias performance

- Low high-frequency losses

- Isotropic magnetic properties, enabling complex 3D magnetic paths

Typical applications include:

- PFC inductors

- Output filter inductors

- High-frequency transformers

- Specialized motor designs

Amorphous and Nanocrystalline Alloys

Amorphous and nanocrystalline alloys feature ultra-high permeability and extremely low core loss.

They are often selected when:

- High efficiency is critical

- Compact size is required

- Thermal margins are limited

Common applications include:

- High-frequency, high-efficiency transformers

- Precision sensors

- Common-mode chokes

How Engineers Select the Right Soft Magnetic Material

There is no universal “best” soft magnetic material.

Material selection depends on balancing frequency, flux density, DC bias, efficiency, and cost.

- High frequency and high flux density

→ Nanocrystalline alloys or SMC cores - Large DC bias current or complex magnetic structures

→ Metal powder cores / SMC - Cost-sensitive, fixed-frequency designs

→ Standard ferrites or iron-based alloys - Ultra-high-frequency or EMI suppression

→ NiZn ferrites

Together, these material families form a complete soft magnetic material system,

covering applications from power frequency to high frequency,

and from high-power to small-signal designs.

Why Early Material Selection Matters

As switching frequencies continue to rise and efficiency requirements tighten,

soft magnetic materials are no longer a commodity choice.

Early involvement in material selection helps:

- Reduce core loss and thermal issues

- Avoid costly redesign cycles

- Improve power density and system reliability

For engineers, understanding magnetic materials is increasingly a design advantage,

not just a materials choice.

Technical Support for Material Selection

If you are evaluating soft magnetic materials for a new or existing design,

early technical discussion can significantly shorten development time.

We support engineers with application-oriented magnetic material selection

and sourcing solutions across multiple material families.

👉 Let’s discuss your application.