Parylene is a conformal polymer coating material synthesized from p-xylene monomers. It was developed by Union Carbide Corporation in the mid-1960s. Through a vacuum vapor deposition process, Parylene forms a uniform, pinhole-free, and transparent thin film on the substrate surface. It provides excellent moisture, corrosion, and chemical resistance as well as electrical insulation, and can cover complex geometries including micro-gaps. Based on molecular structure differences, it is mainly categorized into types such as N, C, D, and HT. Type N features high permeability, type C offers superior moisture barrier properties, and type HT can withstand temperatures up to 450°C.

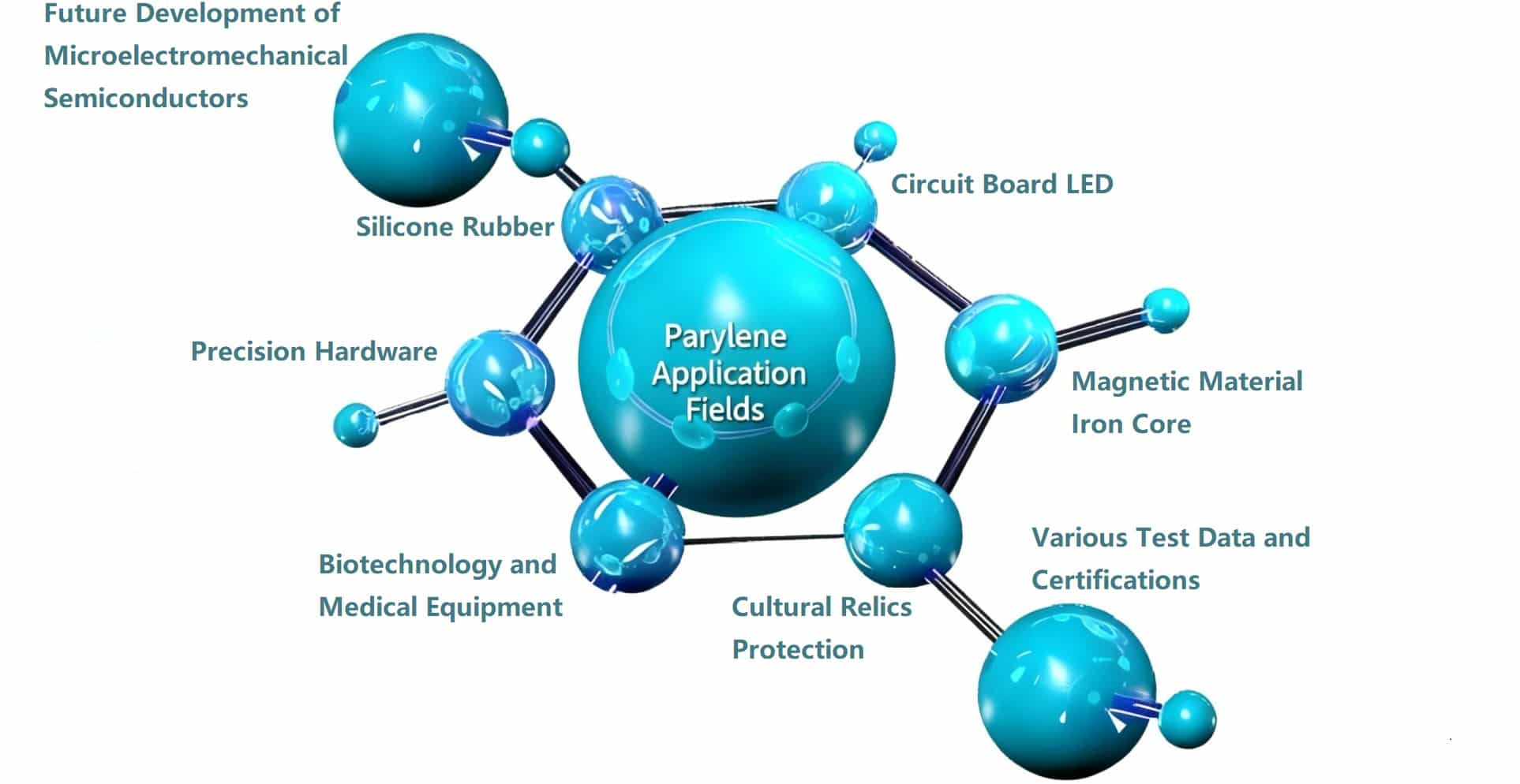

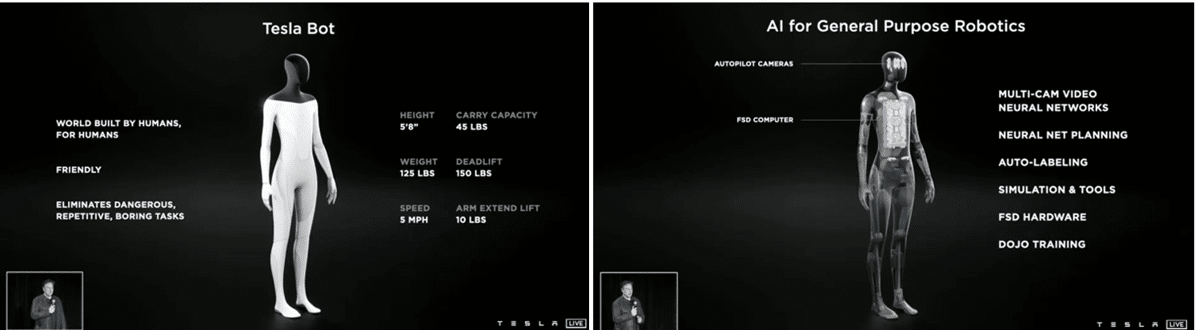

Initially, Parylene was used for microelectronic packaging and magnetic material protection. With technological advancements, its applications have expanded to biomedical, aerospace, and consumer electronics fields. Since the 2000s, companies like Apple and Tesla have adopted Parylene coatings for the protection of mobile phones, earphones, and electric vehicle circuit boards, significantly increasing market visibility. After obtaining FDA approval, Parylene became an optional coating for implantable medical devices and has demonstrated advantages in ultra-lightweight protection for avionics components and precision coatings for sensors. In China, domestic enterprises have achieved coating uniformity within ±5% and developed multifunctional composite coatings through independent R&D, gradually entering supply chains in semiconductor and communication industries .

Parylene, known in Chinese as 聚对二甲苯 (poly-p-xylylene), is a protective polymer material that can be deposited through a vacuum vapor deposition process. Due to the strong penetrability of its active molecules, Parylene can form a pinhole-free, uniform, and transparent insulating coating inside, underneath, and around components. This provides a complete and high-quality protective layer that resists acids, alkalis, salt spray, mold, and various corrosive gases. Since Parylene is not applied in liquid form, issues such as pooling, bridging, or meniscus formation do not occur during the coating process.

Why is Parylene coating used for NdFeB permanent magnets?

NdFeB (neodymium-iron-boron) permanent magnets are high-performance magnetic materials, but they are highly unstable when exposed to air. For larger magnets, protective coatings such as electroplating or epoxy electrophoretic coatings are commonly used. However, for smaller magnets—especially ring-shaped and cylindrical types—traditional coating methods often fail to meet performance requirements.

Parylene’s unique vapor deposition process and outstanding material properties make it ideal for providing complete, pinhole-free coverage on small and ultra-small magnets. Magnets coated with Parylene can withstand immersion in hydrochloric acid for more than 10 days without corrosion. As a result, Parylene coatings are now widely adopted internationally as insulation and protective layers for small and miniature magnetic components.