Permanent magnet assemblies are one of the core technologies enabling nanometer-level ultra-precision motion in modern lithography machines. To date, many leading universities have been actively conducting research and gradually advancing industrialization in this field.

Its core applications and value are reflected in the following three aspects:

1. Enabling non-contact actuation

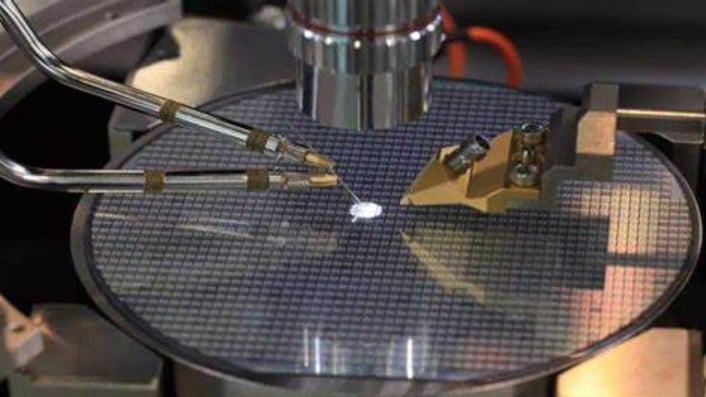

By employing permanent magnet planar motor technology, the system integrates an array of permanent magnets with electromagnetic coils. Through magnetic force actuation, moving components (such as the wafer stage) achieve non-contact, frictionless “magnetic levitation” motion on a two-dimensional plane. This fundamentally eliminates wear, vibration, and heat caused by traditional mechanical friction, forming the foundation for achieving ultra-high precision and high-speed motion.

2. Delivering high precision and dynamic performance

High precision: Permanent magnets provide a strong and stable static magnetic field. Combined with high-precision sensors and advanced control systems, the setup can achieve repeatable positioning accuracy at the nanometer or even sub-nanometer level.

High speed and high acceleration:The direct-drive configuration eliminates intermediate transmission mechanisms, resulting in low inertia and enabling the stage to perform scanning motions with extremely high acceleration. This significantly enhances the throughput of the lithography machine.

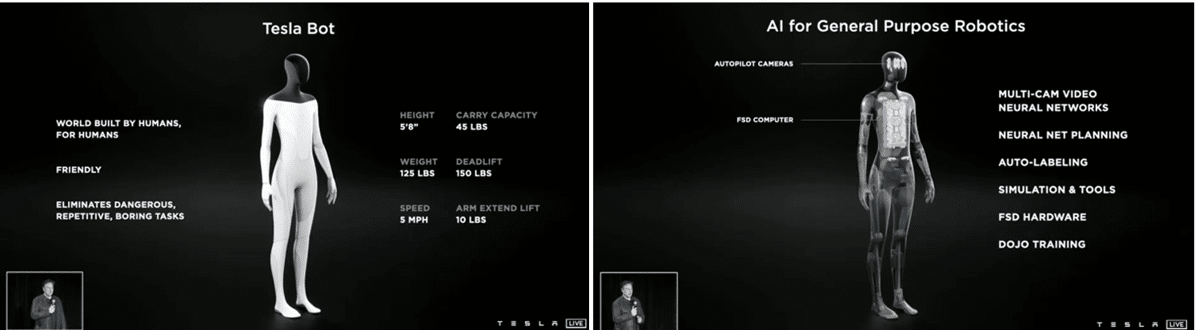

3. Supporting macro–micro composite structures:

In advanced stage designs integrating macro- and micro-motion systems:

- Macro stage: Typically driven by permanent magnet linear motors, responsible for large-stroke and high-speed movements.

- Micro stage: Utilizes a six-degree-of-freedom magnetic levitation mechanism based on permanent magnets to achieve nanometer-level fine adjustments and compensations on top of the macro motion, ultimately ensuring exceptionally high overlay accuracy.

In summary, permanent magnet assemblies enable frictionless and highly stable magnetic levitation actuation, providing the physical foundation required for ultra-high precision, ultra-high speed, and ultra-high reliability in lithography stage motion control systems. They are an indispensable technology that empowers lithography machines to perform precision lithographic operations.