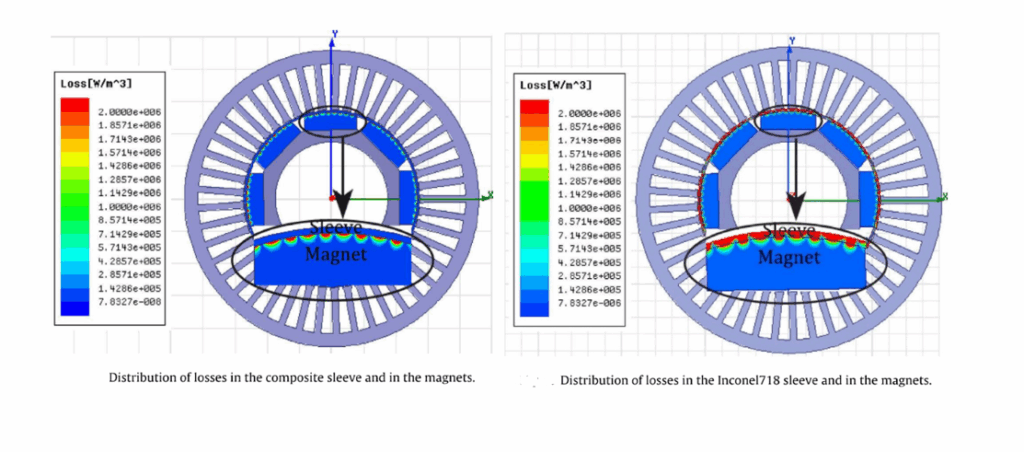

High-speed permanent magnet (PM) motors offer significant advantages, including high power density, efficiency, and compact design. However, when non-laminated steel is used for the rotor, eddy current losses can become severe, potentially causing irreversible demagnetization of the permanent magnets. Research has shown that replacing the high-conductivity steel sleeve with low-conductivity carbon fiber composite materials effectively reduces rotor losses, enhancing performance and reliability.

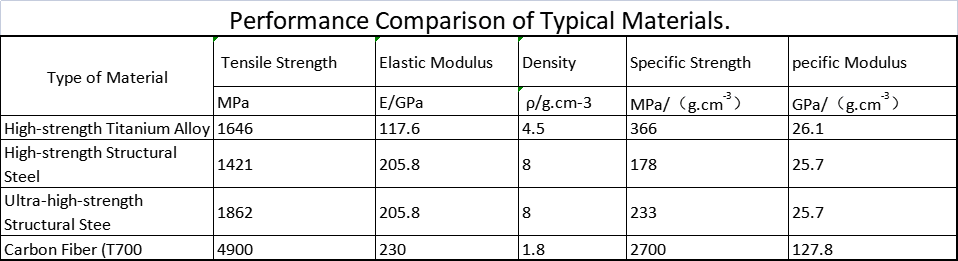

Carbon Fiber Material Properties

Carbon fiber is a high-performance material composed of over 95% carbon. It combines exceptional mechanical strength, chemical stability, and electrical properties, earning it the reputation of the “King of New Materials.” Due to its strategic importance in both military and civilian applications and its high cost, carbon fiber is often referred to as “black gold.”

Currently, the majority of carbon fiber is derived from polyacrylonitrile (PAN) fiber. The conversion of PAN fiber to carbon fiber involves three key steps:

- Pre-oxidation: PAN fibers are oxidized at temperatures below 300°C, causing dehydrogenation and cyclization, forming a heat-resistant structure in preparation for carbonization.

- Carbonization: Fibers are heated to 1000–1500°C in an inert atmosphere. Non-carbon atoms and unstable components are removed, resulting in a disordered graphite-like structure with a carbon content exceeding 92%.

- Graphitization (for high-modulus fibers): Carbonized fibers are further treated at 2000–3000°C to produce ultra-high modulus fibers.

For structural composite materials, matrices are typically epoxy, phenolic, polyimide, or similar resins. Curing agents and additives are incorporated to ensure proper crosslinking and processability. The working temperature of curing agents is generally below 130°C but can go up to 185°C depending on the resin system.

Manufacturing Methods for Carbon Fiber Rotors

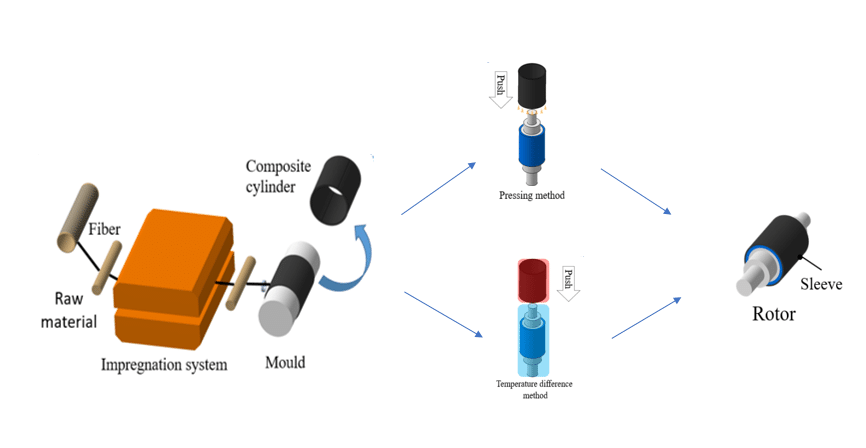

The two conventional methods for producing carbon fiber rotors are the press-fitting method and the tension-tension winding method.

1. Press-Fitting Method

This method relies on an interference fit between the permanent magnet and the carbon fiber sleeve. Upon assembly, elastic deformation of the materials generates compressive stress at the contact surfaces, ensuring the stability of the permanent magnet if the interference fit is properly selected.

Common interference fit assembly techniques include press-fitting, cold assembly, and hot-fit methods. However, due to the low thermal expansion coefficients of both carbon fiber composites and permanent magnets, only the press-fitting method is suitable.

Process flow for press-fitting:

- Fiber bundles are wound layer by layer onto a mold that defines the inner diameter of the sleeve.

- After reaching the required thickness, the sleeve is cured and demolded.

- The permanent magnet is pressed into the sleeve using a hydraulic press.

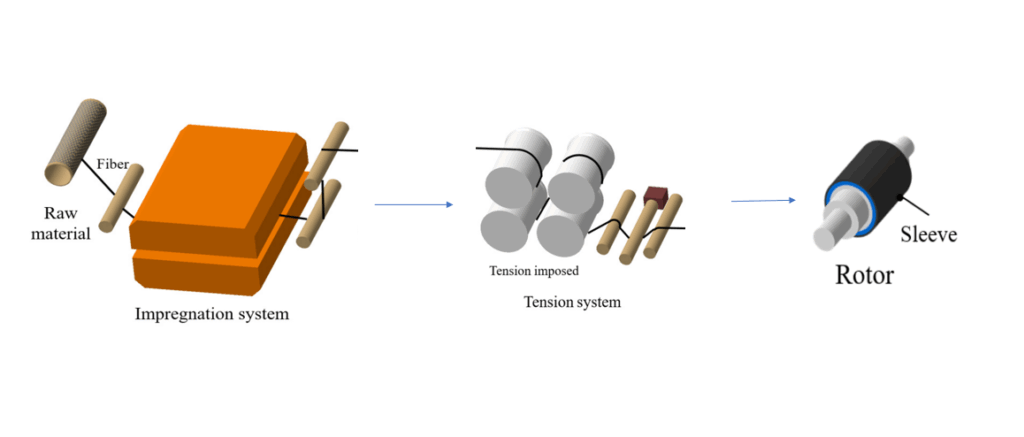

2. Tension-Tension Winding Method

In this approach, no mold is required. Fibers are directly wound onto the permanent magnet surface under controlled tension. After curing, the carbon fiber sleeve imposes pre-compressive stress on the permanent magnet, protecting its structural integrity.

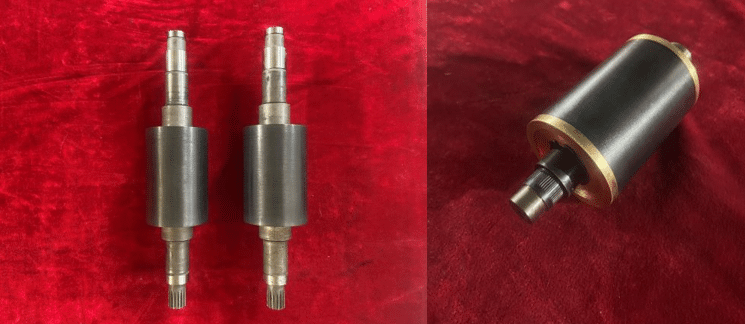

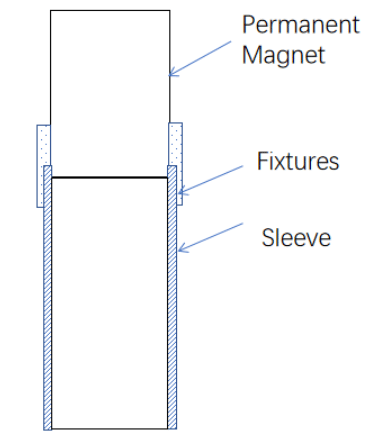

Fixture Design and Alignment

Accurate alignment between the permanent magnet and the carbon fiber sleeve is critical. Custom fixtures are often designed to ensure precise positioning. Hangzhou Permanent Magnet Group has independent fixture design capabilities to meet the requirements of diverse rotor geometries, ensuring alignment accuracy and repeatability.

Quality Assurance and Testing

After assembly, rotors undergo comprehensive checks, including runout and form tolerance inspections, outer diameter verification, and positional tolerance checks. We are equipped with a complete set of advanced inspection instruments and a skilled technical team to perform testing on finished products. Early-stage collaboration with customers ensures that rotors meet precise performance and dimensional requirements.