Main parameters of permanent magnetic materials:

- Magnetic performance indicators: Remanence (Br), coercivity (Hcb), intrinsic coercivity (Hcj), maximum energy product ((BH)max), temperature coefficient of remanence, and temperature coefficient of coercivity, etc.

- Physical properties: Density, electrical conductivity, thermal conductivity, coefficient of thermal expansion, temperature resistance, etc.

- Chemical properties: Corrosion resistance, oxidation resistance, thermal stability, etc.

- Mechanical properties: Vickers hardness, compressive (tensile) strength, impact toughness, etc.

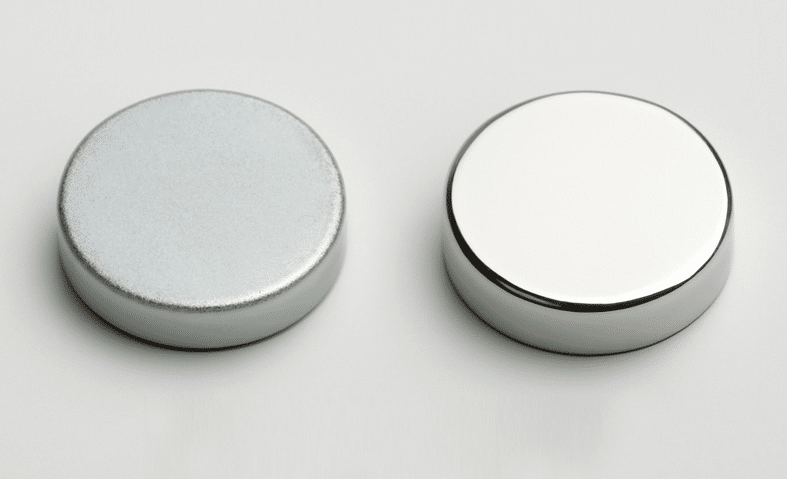

Main classifications of permanent magnetic materials:

According to their magnetic properties and stages of development, permanent magnetic materials can be divided into three categories: metallic permanent magnets, ferrite permanent magnets, and rare earth permanent magnets. The main comparisons are as follows:

| Type | Category | Composition | General Characteristics |

| Metal Permanent Magnets | Alnico (AlNiCo) | Composed of iron and ferromagnetic elements | Low coercivity, hard texture, widely used in electrical instruments and communication devices. |

| FeCrCo | Used for manufacturing small magnetic components with small cross-sections and complex shapes, such as speakers, tachometers, and hysteresis motors. | ||

| PtCo | Excellent chemical corrosion resistance, can work in acidic, alkaline, and saline media; very expensive, mainly used in aerospace, aeronautical instruments, measuring instruments, and electronic watches. | ||

| Ferrite Permanent Magnets | Sintered ferrite (Sr-ferrite, Ba-ferrite) | Mainly composed of strontium oxide or barium oxide and ferric oxide | Abundant raw materials, low cost, simple preparation process, excellent oxidation resistance; high-performance ferrites are widely used in automotive and home appliance industries. |

| Bonded ferrite (Sr-ferrite, Ba-ferrite) | |||

| Rare Earth Permanent Magnets | SmCo 1:5 / 2:17 series (sintered/bonded) | Composed of rare earth metal elements (RE) and transition metal elements | Excellent magnetic stability, high-temperature performance, outstanding oxidation and corrosion resistance; widely used in aerospace, defense industry, and high-end motors. |

| NdFeB (sintered, bonded, hot-pressed) | High-performance NdFeB applications cover traditional and new energy vehicles, wind power generation, electronic devices, and household appliances; low-end NdFeB is mainly used in magnetic adsorption, magnetic separation, e-bikes, luggage buckles, door latches, toys, etc. | ||

| Fe-N permanent magnet (Re-Fe-N system, bonded) | In the R&D and promotion stage; mainly applied in magnetic adsorption. Compared with NdFeB, it has lower cost due to the absence of expensive rare earth elements. |

Based on the various characteristics of the permanent magnetic materials mentioned above, and taking into account the information provided by the customer, the required type of permanent magnet or permanent magnet assembly can generally be summarized into the following cases:

| Scenario | Information Provided | Process for Handling Procurement Requirements |

| Scenario ① | The customer clearly understands their needs and provides design drawings of the permanent magnet or magnetic assembly | Step ①:(1) Determine the type of permanent magnet, dimensions (dimensional tolerance, geometric tolerance), whether coating is required and its type, magnetization direction, finished product testing requirements (magnetic deviation angle, flux/magnetic moment, aging test, salt spray test, etc.), and whether special customized molds are needed.(2) Based on accessory drawings, evaluate machining methods, dimensional/geometric tolerances, machining difficulty, assembly methods, and whether assembly fixtures/overall testing after assembly are required.(3) Other requirements (packaging, transportation, etc.). Step ②:Clarify the required quantity of permanent magnets, accessories, assembly steps, auxiliary material consumption, and assembly difficulty. Batch orders usually enjoy lower unit prices, while small-batch or sample orders may incur higher costs. Step ③:Confirm customer’s delivery requirements and provide the final quotation. |

| Scenario ② | The customer specifies performance requirements (e.g., suction force, surface magnetic field within limited space, torque, low cost, etc.) and requires the magnet manufacturer to select the appropriate magnet type and evaluate the assembly structure, providing design drawings | Step ①:According to the customer’s usage requirements, use magnetic simulation software (e.g., Maxwell, COMSOL) or multiphysics coupling software for more complex cases to determine the basic performance of the magnet. Combine environmental conditions such as operating temperature, cost control, and dimensional constraints to finalize the type and performance of the magnet as well as the overall assembly structure. Step ②:Repeat Step ① (1)(2)(3) from Scenario ①. Step ③:Clarify the required quantity of permanent magnets, accessories, assembly steps, auxiliary material consumption, and assembly difficulty. Batch orders usually enjoy lower unit prices, while small-batch or sample orders may incur higher costs. Step ④:Confirm customer’s delivery requirements and provide the final quotation. |

| Scenario ③ | The customer wants to benchmark competitors and can provide samples of permanent magnets or magnetic assemblies | Step ①:Test the samples provided by the customer (magnetic performance, spatial magnetic field, material composition, dimensional measurements, etc.). Several rounds of iterative development are usually required, and a preliminary quotation can be provided. Subsequent handling steps are consistent with Step ①/②/③ in Scenario ①. |

| Scenario ④ | The customer wants to benchmark competitors but cannot provide samples of permanent magnets or magnetic assemblies | In this case, the customer is unclear about usage requirements. Compared with Scenario ②, the difficulty is higher. Quotations for sample development are usually higher, and batch prices cannot yet be provided. Initial quotations should include development costs, the inclusion of which depends on project difficulty. After iterative development, the process is generally consistent with Scenario ②. |

These are some typical handling scenarios. The specific steps for addressing customer requirements can be flexibly adjusted depending on the completeness of the information received from the client. The above is a summary based on daily work practices, and there may still be omissions or areas not fully covered. Further discussion and supplementation are welcome!