At present, the main types of permanent magnets include Neodymium-Iron-Boron (NdFeB), Samarium-Cobalt (SmCo), AlNiCo, and Ferrite. Each type of permanent magnet has its own unique performance characteristics. To prevent degradation of their properties during use, there are several common precautions and influencing factors that must be carefully considered, including:

Main Factors Affecting Permanent Magnet Performance

| No. | Influencing Factor | Description |

| ① | Temperature (High or Low) | Each type or grade of permanent magnet has its own characteristic temperature tolerance range. It is generally known that when the temperature exceeds a certain threshold, magnetic performance may deteriorate as the magnetic domains inside the magnet become disordered, commonly referred to as demagnetization under high temperature. Special attention should be paid to situations where permanent magnets may experience partial demagnetization at relatively low temperatures. For applications involving extreme temperatures, this factor must be carefully considered. |

| ② | Humidity | Humidity has a direct effect on permanent magnets. For example, rare-earth magnets are prone to oxidation and corrosion under humid conditions, resulting in irreversible damage to the chemical structure and deterioration of magnetic performance. Although protective coatings are widely used to mitigate such risks, they cannot completely eliminate the impact of humidity on long-term stability. Since different magnets exhibit varying sensitivity to humidity, appropriate protective measures should be taken according to application requirements. |

| ③ | Chemical Substances (Strong Acids or Alkalis) | In environments containing strong acids or alkalis, the chemical structure of permanent magnets may be destroyed, leading to unavoidable performance degradation. |

| ④ | Severe Vibration or Mechanical Impact | Continuous vibration or strong mechanical impact can cause internal microstructural damage within the magnet, reducing its stability and magnetic strength. Even though permanent magnets are generally robust, repeated vibration or impact can eventually lead to irreversible performance loss. |

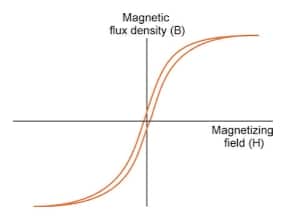

| ⑤ | Strong External Magnetic Fields or Reverse Magnetic Fields | The magnetization of a permanent magnet is typically achieved through a strong applied magnetic field. If a permanent magnet is exposed to another strong magnetic field (especially one in the reverse direction), its internal magnetic domain structure may be disturbed. After exceeding a certain critical field strength, this disturbance can result in partial or complete demagnetization, permanently altering the magnetic properties. |

The factors listed above illustrate some of the key influences on the performance of permanent magnets during use. To address these issues, certain proper protection and storage measures for permanent magnets can also be applied:

Protective Measures and Storage Guidelines for Permanent Magnets

| No. | Protective / Storage Measure | Description |

| ① | Avoid Exposure to High Temperature and Direct Sunlight | Permanent magnets should be kept away from heat sources and direct sunlight. This helps ensure they remain within their temperature tolerance range and prevents demagnetization. |

| ② | Moisture and Corrosion Protection | The storage environment for permanent magnets should be kept dry. Desiccants or vacuum-sealed packaging may be used to prevent corrosion-related demagnetization caused by high humidity. |

| ③ | Shock-Resistant Packaging | Individual magnets or multiple magnets should be packed with protective materials such as foam, wooden separators, or other effective shock-absorbing methods. This minimizes the risk of vibration or impact damage during transportation and storage. |